hot cold pack manufacturers

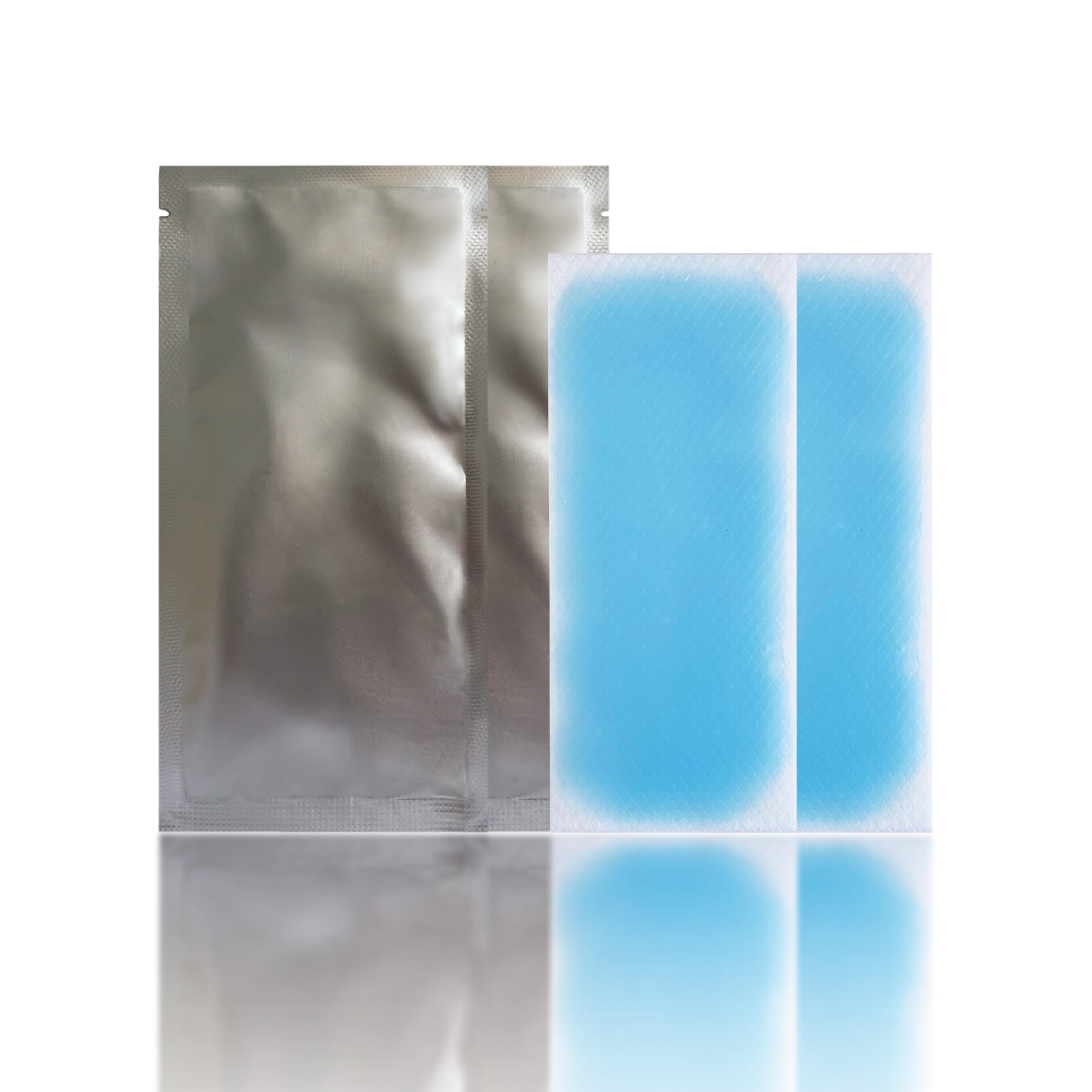

Hot cold pack manufacturers are specialized companies dedicated to producing versatile therapeutic products that provide both heating and cooling solutions for various applications. These manufacturers employ advanced manufacturing processes and high-quality materials to create packs that can maintain consistent temperatures for extended periods. The production facilities utilize state-of-the-art technology to ensure precise temperature control and durability in their products. These manufacturers typically offer a diverse range of products, from small personal-use packs to large industrial-scale solutions. Their manufacturing processes incorporate rigorous quality control measures and comply with international safety standards. The products are designed with multiple layers of protection, including leak-proof sealing and durable outer casings. Many manufacturers also focus on developing eco-friendly solutions and sustainable manufacturing practices. Their products find applications in healthcare facilities, sports medicine, physical therapy, and personal use. The manufacturing process includes careful selection of gel or liquid compounds that can effectively retain both hot and cold temperatures. Advanced packaging techniques ensure extended shelf life and maintain product efficacy. These manufacturers often provide customization options to meet specific client requirements, whether for medical facilities or retail distribution.