ice pack factory

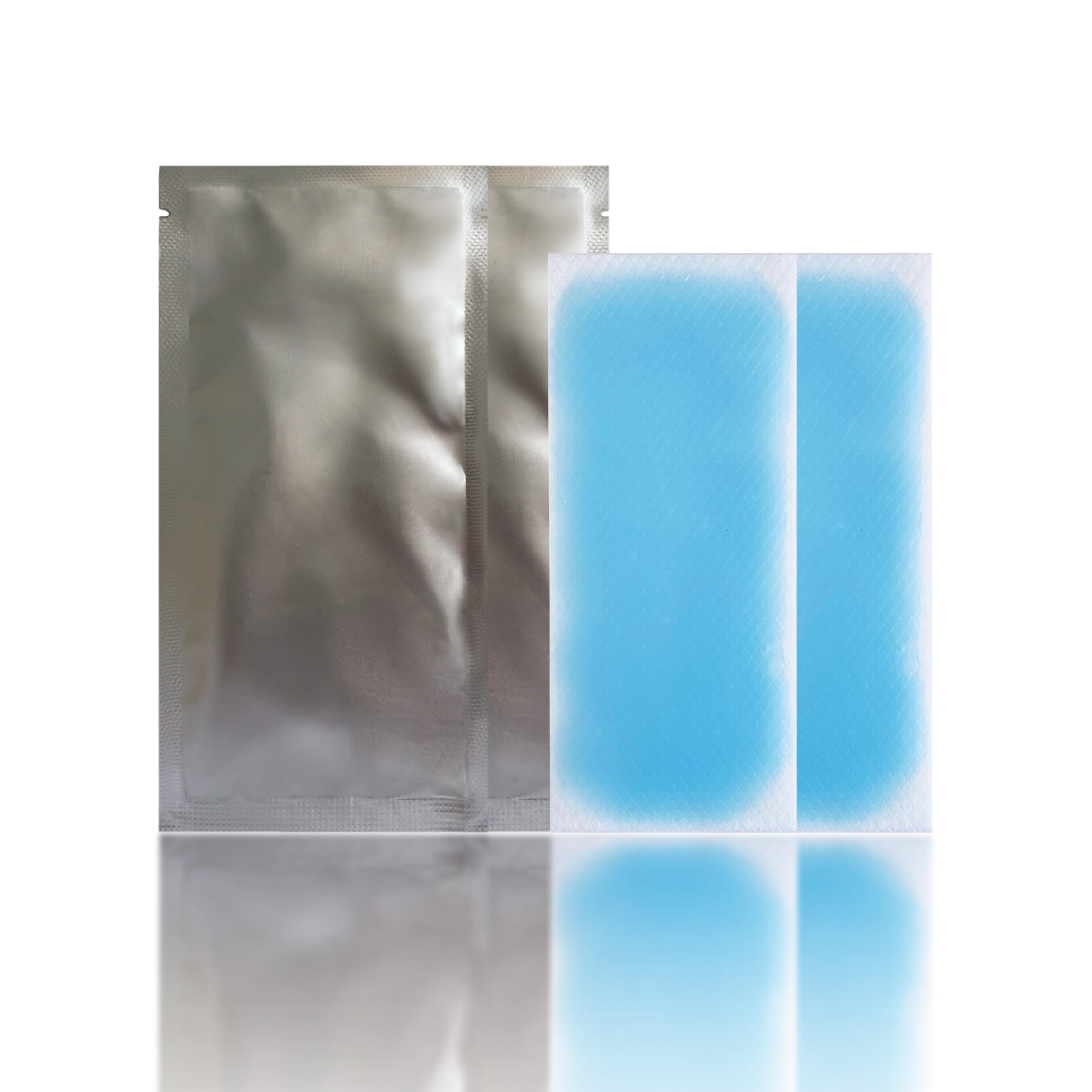

An ice pack factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality freezable gel packs and ice packs for various cooling applications. These facilities utilize advanced automation systems and precision engineering to create reliable cooling solutions. The production line typically incorporates specialized mixing equipment for gel formulation, automated filling systems, and quality control stations that ensure each ice pack meets strict standards. Modern ice pack factories employ thermal regulation technology to maintain consistent product quality and implement efficient packaging systems for optimal distribution. The facility's operations include raw material processing, gel mixture preparation, pack formation, sealing, quality testing, and packaging stages. Advanced manufacturing processes ensure the products maintain their cooling efficiency and durability. These factories often feature research and development departments that continually work on improving gel formulations and pack designs to meet evolving market demands. Environmental control systems maintain clean room conditions where necessary, while automated monitoring systems track production metrics and maintain quality standards throughout the manufacturing process. The facility's output serves various industries, including medical, pharmaceutical, food service, and consumer markets, providing essential cooling solutions for temperature-sensitive applications.